With a new DEC motor drive in place, I decided I’d take apart my old DEC drive gearbox to see if it could be improved at all. Once split from the motor I used two pairs of pliers to hold one of the gearbox sideplates close to each of the three brass pillars joining them and levering the pliers against each other eased the plates apart. They actually came apart quite easily, and I was able to separate them and remove all the gears (and a small spacer):

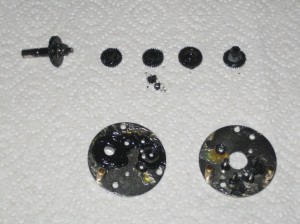

To remove the remains of the nasty black goop I soaked everything for twenty-four hours in isopropanol and then scrubbed the parts with a small brush. It wasn’t a perfect result, but not too bad:

Then it was just a case of attempting reassembly, lubricating everything as I went. There are four shafts excluding the output shaft. If we count them in order from the one on the right in my picture, the fourth shaft is larger in diameter and will only accept one of the brass gears, leaving two others plus the nylon one. The first gear to go back is one of the brass gears with the smaller bore and larger teeth on the bigger of the two gears. It goes with the smaller gear up on shaft three:

That’s followed by the only gear that fits on shaft four, also smaller gear up:

Next up is the nylon gear that’s driven by the motor, on shaft one. Smaller gear up again:

And then the last brass gear, on shaft two and this time smaller gear down:

The spacer goes back next, above the gear on shaft three:

And finally the output shaft is put back into place:

With everything in place I then slid the upper sideplate down over the output shaft and with just pressure from my fingers it snapped neatly back into place on the three brass pillars:

The most surprising thing about the entire process was not that everything went back together so nicely, but that once done, the gearbox turned very easily as I turned the output shaft in my fingers. When I started it was possible to turn the gearbox, but it was very stiff. Sadly it still has more backlash than my new one, so I won’t be putting it back on the mount.

Another point to note is that the sideplates are not identical as the bushings for the output shaft are different on each, but they do have five unused holes each that are aligned with each other. Two appear to be the same size as the ones for the existing brass pillars whilst the others look the same size as some of the gear shafts. I’d hazard a guess that Synta use the same sideplates for several different gearboxes and just have different sets of gears to fit in them.