Sewing machines… They work by magic, don’t they?

My daughter has been using my wife’s machine to make clothes and bags from old unwanted material such as pairs of jeans and shirts that I no longer fit into:

Unfortunately the machine had somehow gone wrong and had no tension on the upper thread at any setting of the tensioning wheel. Peering in though the gaps in the “bodywork” it appeared that the two discs that are supposed to drag on the thread to produce tension weren’t even touching. After a discussion in which we decided that it would cost more to have it serviced professionally than it would to buy a completely new one I decided I might as well take it apart and see how much damage I could do. There can’t be that many “ping-fsckits”[1] inside, surely?

We found a service manual online that explained how to remove the case, but having done so I couldn’t work out why the tensioner wheels weren’t working correctly so I decided to remove the mechanism for a closer look. At which point it exploded into a pile of springs, discs and washers. After at least one false start I managed to put everything back together and realised that the tensioning mechanism was now working correctly.

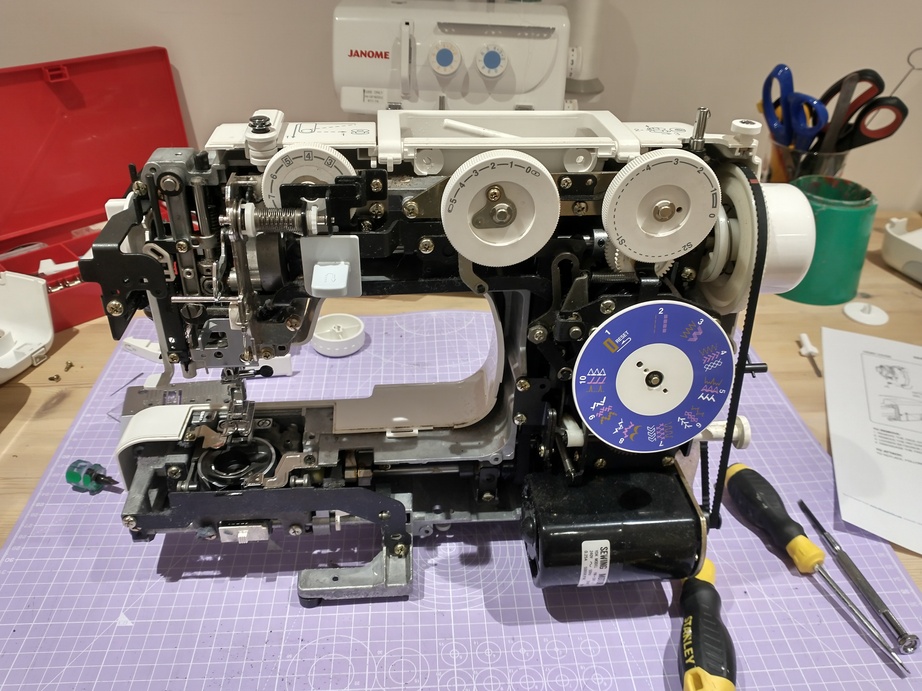

A semi-naked sewing machine

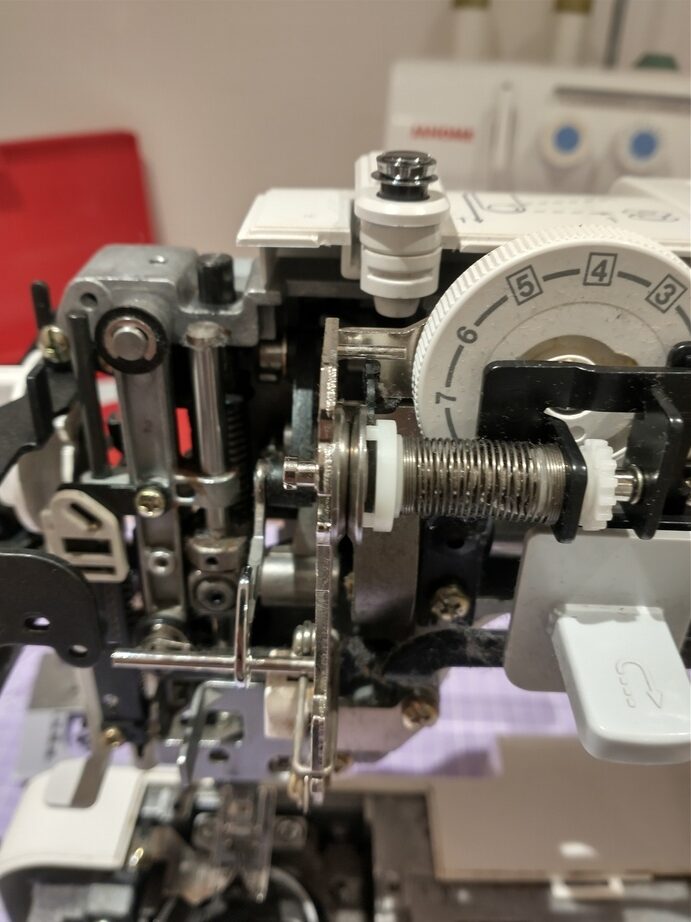

Right in the centre here is the tensioning mechanism in case you’ve not seen one before.

I have no idea why it’s now working and what problem has been corrected which is quite irritating given that I therefore have no idea how to stop it happening again, but I’m happy enough that it has saved me a packet which I can now spend on an Oxalic Acid vaporiser for my bees 😀

All I need now is a suitable spring balance so I can correctly set the tension range.